JMP Statistical Thinking for Industrial Problem Solving (A00-910) is a professional certification exam that is designed for individuals seeking a career in the field of industrial problem-solving. This exam tests an individual’s knowledge and skills in applying statistical concepts to industrial problems. It is designed to test an individual’s proficiency in using JMP software for solving statistical problems in an industrial setting. Some of the skills required for this exam are:

- The exam requires a good understanding of statistical concepts like probability, hypothesis testing, regression analysis, ANOVA, etc. The candidate should be able to apply these concepts to real-world industrial problems.

- The exam requires a good working knowledge of the JMP software. The candidate should be able to use the software to perform statistical analysis, visualize data, and interpret the results. Familiarity with the various statistical tools and platforms available in JMP is also important.

- Having strong problem-solving skills. The candidate should be able to analyze complex industrial problems and apply statistical techniques to arrive at a solution. The candidate should be able to identify the appropriate statistical techniques to use and interpret the results in a meaningful way.

- The candidate should have good communication skills and be able to present the results of their analysis in a clear and concise manner, both in written and verbal form. The candidate should be able to explain their findings to non-technical stakeholders and suggest appropriate actions based on the analysis.

Getting ready for this test might seem hard, but if you use the correct tools and methods, it can be a satisfying journey. In this blog, we’ll give you some advice and tricks on how to get ready for the JMP Statistical Thinking for Industrial Problem Solving (A00-910) exam.

Glossary of JMP Statistical Thinking for Industrial Problem Solving Terminology

JMP Statistical Thinking for Industrial Problem Solving is a set of techniques and tools that help professionals analyze and solve problems in an industrial setting. This glossary provides a list of common terms used in Statistical Thinking for Industrial Problem Solving and provides a starting point for anyone looking to learn more about the concepts and methods used in Industrial Problem Solving.

- DOE (Design of Experiments): A method used to determine the cause-and-effect relationships between variables by systematically varying one or more inputs and measuring the output.

- ANOVA (Analysis of Variance): A way of using numbers to see if there’s a big difference between the averages of two or more groups.

- Regression Analysis: A statistical technique used to figure out how a main thing (dependent variable) is connected to one or more other things (independent variables).

- Hypothesis Testing: A statistical method used to determine the likelihood of a hypothesis being true or false based on a sample of data.

- Process Capability Analysis: A statistical method used to measure the ability of a process to meet specifications.

- Control Charts: A tool used to monitor a process over time and detect any changes or deviations from the expected behavior.

- Six Sigma: A data-driven approach to quality management that aims to reduce variability and defects in a process.

- Pareto Chart: A graph that displays the relative frequency or size of problems in descending order of importance.

- Root Cause Analysis: A method used to identify the underlying cause(s) of a problem or defect.

- Fishbone Diagram: A tool used to identify possible causes of a problem by organizing them into categories.

- Capability Analysis: A method used to assess a process’s ability to meet customer requirements and specifications by analyzing its performance data.

- Design Space: The range of input variables and their corresponding values that lead to acceptable process performance.

- Process Mapping: A tool used for visually representing the steps in a process and the relationships between them.

- Statistical Process Control (SPC): A method used for monitoring and controlling a process by using statistical techniques for identifying and responding to changes in the process.

- Tolerance Analysis: A method used to determine the maximum allowable variation in a product’s dimensions or other characteristics based on customer requirements and specifications.

- Factorial Design: A type of DOE that involves varying multiple factors simultaneously to determine their combined effects on process output.

- Response Surface Methodology (RSM): A statistical technique used to model and optimize a process output by varying multiple input variables.

- Design for Six Sigma (DFSS): A methodology that integrates the principles of Six Sigma into the design and development of products and processes to ensure they meet customer requirements and specifications.

- Statistical Modeling: The process of building a mathematical model that describes the relationship between a response variable and one or more predictor variables.

- Multivariate Analysis: A statistical technique used to analyze and model data that involves multiple variables or dimensions.

- Analysis of Means (ANOM): A statistical technique used to compare the means of multiple groups and identify which groups are significantly different from each other.

- Response Optimization: A process of finding the input settings that result in the optimal response or outcome, based on a mathematical model of the system.

- Nonparametric Statistics: A statistical technique used when the data does not meet the assumptions of traditional parametric statistics, such as normal distribution or equal variance.

- Robust Design: A design approach that focuses on creating products and processes that are insensitive to variation and can perform well under different operating conditions.

- Taguchi Methods: A set of methods developed by Genichi Taguchi to improve product and process quality by optimizing the design and reducing variation.

- Monte Carlo Simulation: A method used for modeling the behavior of a system or process by simulating random variations in its inputs and examining the resulting outputs.

- Quality Function Deployment (QFD): A structured process for translating customer requirements into specific design and engineering specifications.

- Gage R&R: A method used to assess the measurement system’s ability to measure a process’s output accurately and consistently.

- Process Improvement: A continuous effort to identify and eliminate waste, reduce variability, and improve efficiency and effectiveness in a process.

- Statistical Quality Control (SQC): A set of methods and tools used to monitor and control a process’s quality by using statistical techniques to detect and prevent defects.

JMP Statistical Thinking for Industrial Problem Solving is a powerful set of tools and techniques that can help professionals solve complex problems in an industrial setting. By understanding the common terminology used in JMP Statistical Thinking, professionals can better understand and communicate their findings to colleagues and stakeholders. This glossary provides a starting point for anyone looking to learn more about the concepts and methods used in JMP Statistical Thinking for Industrial Problem Solving.

Study Guide for JMP Statistical Thinking for Industrial Problem Solving (A00-910) Exam

To help users understand the software’s features and applications, JMP offers a range of official training courses and study resources. These courses and resources are designed to provide users with the knowledge and skills needed to effectively use JMP for industrial problem-solving.

Official Training Courses: JMP offers a range of official training courses that cover different aspects of statistical thinking for industrial problem-solving. These courses are designed to cater to users with varying levels of expertise, from beginners to advanced users. Some of the popular courses include:

- JMP Software: Statistical Thinking for Industrial Problem Solving – This foundational course introduces users to the basics of statistical thinking and how it can be applied to industrial problem-solving using JMP software. The course covers topics such as data visualization, descriptive statistics, hypothesis testing, and regression analysis. The course is available both as a self-paced online course and as a traditional classroom course.

- JMP Software: Design Experiments for Industrial Problem Solving – This course focuses on the use of the design of experiments (DOE) to identify and optimize process parameters in industrial settings. The course covers topics such as statistical models, full and fractional factorial designs, response surface methodology, and mixture designs. The course is available both as a self-paced online course and as a traditional classroom course.

- JMP Software: Quality and Reliability Analysis for Industrial Problem Solving – This course teaches users how to use JMP software to analyze and improve the quality and reliability of industrial processes. The course covers topics such as statistical process control, measurement systems analysis, reliability analysis, and Design for Six Sigma (DFSS). The course is available both as a self-paced online course and as a traditional classroom course.

- JMP Software: Advanced Analytics for Industrial Problem Solving – This advanced course covers topics such as predictive modeling, data mining, and machine learning using JMP software. The course is designed for users who have completed the Statistical Thinking for Industrial Problem Solving course or have equivalent knowledge. The course is available both as a self-paced online course and as a traditional classroom course.

Study Resources: In addition to training courses, JMP also offers a range of study resources that users can access to improve their knowledge of the software. These resources include:

- JMP User Community – The JMP User Community is a website where people who use JMP can come together, talk to each other, and ask questions to experts about JMP.

- JMP Blog – The JMP Blog features articles written by JMP experts on various topics related to statistical thinking for industrial problem-solving. The blog covers topics such as data visualization, statistical modeling, and process improvement.

- JMP Webinars – JMP Webinars are free online sessions that cover different topics related to statistical thinking and JMP software. The webinars are conducted by JMP experts and cover topics such as data analysis, design of experiments, and quality improvement.

JMP offers a comprehensive set of training courses and study resources to help users master statistical thinking for industrial problem-solving using the JMP software. These courses and resources cater to users with varying levels of expertise and cover a wide range of topics related to statistical analysis, process improvement, and advanced analytics.

Expert Tips to Pass the Statistical Thinking for Industrial Problem Solving Exam

The Statistical Thinking for Industrial Problem Solving exam is an important certification exam that validates one’s knowledge and skills in using statistical tools and techniques to solve industrial problems. Passing this exam requires adequate preparation and a good understanding of statistical concepts.

Expert Tips to Pass the Statistical Thinking for Industrial Problem Solving Exam:

- Understand the exam structure: Before you start preparing for the exam, make sure you understand the structure of the exam, including the number of questions, the time limit, and the types of questions.

- Review basic statistical concepts: Ensure that you have a strong foundation in statistical concepts such as hypothesis testing, regression analysis, and probability distribution.

- Familiarize yourself with statistical software: Be familiar with statistical software such as Minitab, R, or SAS, which you may need to use during the exam.

- Understand the context of industrial problems: Be familiar with the types of problems that are typically encountered in an industrial setting, such as quality control and process improvement.

- Learn to interpret results: It is not enough to know how to perform statistical analyses; you must also be able to interpret the results and draw appropriate conclusions.

- Be familiar with statistical tests: Understand the different types of statistical tests, including t-tests, ANOVA, and chi-square tests, and know when to use each one.

- Understand experimental design: Be familiar with the different types of experimental design, including randomized block design, factorial design, and response surface design, and know when to use each one.

- Be familiar with quality control techniques: Understand quality control techniques such as control charts, Pareto charts, and Ishikawa diagrams, and know how to use them to identify and address quality issues.

- Be familiar with process improvement techniques: Learn about ways to make processes better like Lean Six Sigma, DMAIC, and PDCA. Know how to use them to find and fix problems in processes.

- Be familiar with regression analysis: Understand regression analysis and know how to use it to model relationships between variables and make predictions.

- Be familiar with data visualization: Understand the principles of data visualization and know how to use charts, graphs, and other visual aids to communicate statistical results.

- Be familiar with statistical modeling: Understand statistical modeling and know how to use it to create models that can be used to make predictions or simulate real-world scenarios.

- Know how to write clear and concise reports: Be able to communicate statistical results clearly and concisely in written reports, including the use of tables, charts, and other visual aids.

- Practice with sample questions: Use sample questions from previous exams to practice and gauge your readiness for the exam.

- Use real-life examples: Practice applying statistical concepts to real-life examples to gain a deeper understanding of how to use statistical tools in an industrial setting.

- Stay up-to-date with current trends: Stay informed about current trends and best practices in statistical analysis by reading relevant journals and attending conferences.

- Develop good time management skills: Allocate sufficient time for each question and avoid spending too much time on a single question.

Passing the Statistical Thinking for Industrial Problem Solving exam requires a solid understanding of statistical concepts and the ability to apply them to solve industrial problems. By following these expert tips, you can increase your chances of passing the exam and obtaining the certification. Remember to stay focused, practice regularly, and take care of yourself both physically and mentally. Good luck!

JMP Statistical Thinking for Industrial Problem Solving (A00-910) Exam Guide

The JMP Statistical Thinking for Industrial Problem Solving Terminology exam is a comprehensive assessment designed to evaluate an individual’s understanding of statistical thinking concepts and terminology relevant to industrial problem-solving. The exam covers topics such as hypothesis testing, experimental design, statistical modeling, and data visualization. Individuals who pass the exam demonstrate their ability to apply statistical thinking to real-world industrial problems, making them highly valuable to organizations seeking to improve their decision-making processes.

To prepare for the exam, individuals should study the various statistical thinking concepts and terminology, including the different types of data, statistical distributions, and the fundamental principles of statistical inference. They should also become familiar with the various tools and techniques used in industrial problem-solving, such as the design of experiments, control charts, and regression analysis. It is important for individuals to practice applying these concepts and techniques to real-world problems, as this will help them to develop a deeper understanding of the material and increase their chances of passing the exam.

Passing the JMP Statistical Thinking for Industrial Problem Solving Terminology exam is a valuable accomplishment for individuals looking to advance their careers in fields such as industrial engineering, quality control, and data analysis. By demonstrating their ability to apply statistical thinking concepts and terminology to industrial problems, individuals can position themselves as experts in their field and increase their job opportunities and earning potential. Additionally, passing the exam can help organizations identify employees who are skilled in statistical thinking, making them valuable assets in improving business processes and driving organizational success.

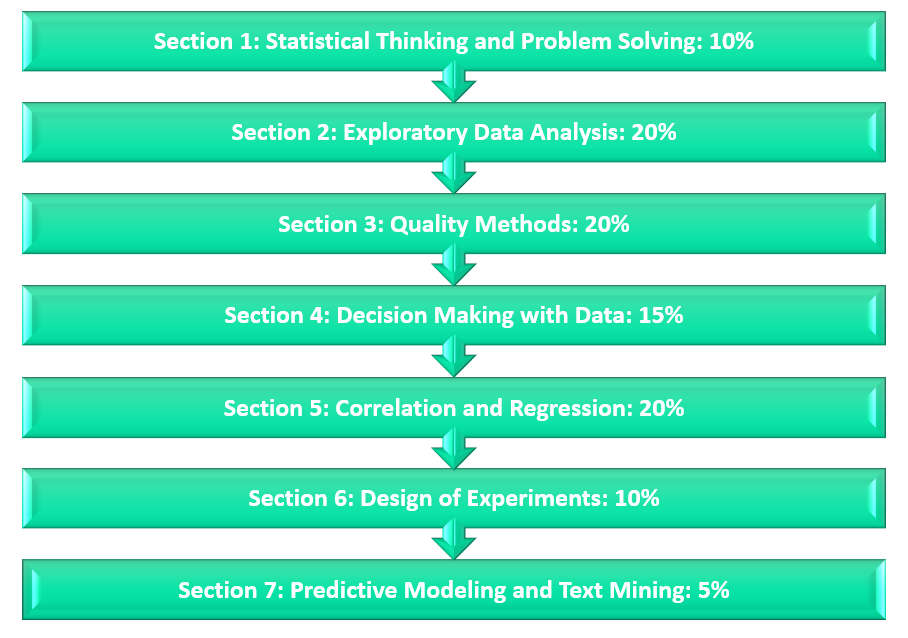

Explore the Exam Topics

What are the skills you will gain from the JMP Statistical Thinking for Industrial Problem Solving certification?

In today’s world, where data is so important, companies really appreciate people who can use statistics to solve problems. The JMP certification in Statistical Thinking for Industrial Problem Solving is a great chance for professionals who want to become experts in using statistics to analyze data and solve problems. This program teaches you practical skills that you can use in different industries.

Skills gained from the JMP Statistical Thinking for Industrial Problem Solving certification:

- Statistical data analysis: The certification program teaches participants how to perform statistical data analysis, including data visualization, hypothesis testing, and statistical modeling. These skills can help professionals analyze data and draw meaningful insights from it.

- Problem-solving techniques: The program focuses on teaching problem-solving techniques that are essential for industrial problem-solving. Participants will learn how to identify problems, develop solutions, and evaluate their effectiveness. These skills are highly valued by businesses that require individuals to solve complex problems.

- Data visualization: The certification program teaches participants how to use data visualization tools to create graphs, charts, and other visual aids that can help communicate data effectively. This skill is important for professionals who need to present data to others, such as managers, stakeholders, or clients.

- Process improvement: The certification program teaches participants how to identify areas for process improvement and implement changes to improve efficiency and effectiveness. These skills can be applied to various industries, such as manufacturing, healthcare, and finance.

- Collaboration and communication: The JMP Statistical Thinking for Industrial Problem Solving certification program also emphasizes the importance of collaboration and communication skills in solving industrial problems. During the program, people learn how to be good team members and explain what they find and suggest to the people they work with. These abilities are very important for folks who work in teams with different kinds of jobs or talk to clients and customers. When people work well together and can talk things out, they usually find better solutions to problems and help companies and industries do better overall.

The program provides practical knowledge that can be applied to real-world situations, making it an excellent investment for professionals who want to advance their careers. With statistical data analysis, problem-solving techniques, data visualization, and process improvement skills, individuals who complete this certification program will be well-equipped to succeed in their careers.

Key Takeaways for the JMP (A00-910) exam

Passing the Statistical Thinking for Industrial Problem Solving exam requires a thorough understanding of the course material and an ability to apply statistical techniques to real-world problems.

Here are some key takeaways to help you pass the Statistical Thinking for Industrial Problem Solving exam:

- Understand the basics of probability theory and statistical inference, including hypothesis testing and confidence intervals.

- Know how to perform and interpret statistical analyses using software such as Minitab or R.

- Understand how to design experiments to test hypotheses and improve processes.

- Understand how to apply statistical process control (SPC) techniques to monitor and control processes.

- Be familiar with regression analysis and its applications in industrial problem-solving.

- Be able to communicate statistical results effectively to both technical and non-technical audiences.

- Practice, practice, practice! Doing practice questions and tests will make you feel more sure of yourself and show you the places where you need to get better.

Passing the Statistical Thinking for Industrial Problem Solving exam requires a strong foundation in statistical theory and practical experience applying statistical techniques to industrial problems. By understanding the key takeaways listed above and practicing regularly, you can increase your chances of passing the exam and becoming a more effective problem solver in an industrial setting.

Experts’ Corner

Preparing for the JMP Statistical Thinking for Industrial Problem Solving (A00-910) exam can be challenging, but with the right approach, you can achieve success. We hope the tips and strategies we have provided in this blog will help you to prepare for this exam with confidence. Don’t forget to get to know how the exam looks, grasp the ideas and methods they will ask about, and practice using example questions and tests. If you do these things, you can do really well on the JMP Statistical Thinking for Industrial Problem Solving (A00-910) test and move ahead in your industrial problem-solving career.

Gain all the necessary skills and bag big salaries with advanced learning skills with expert’s guidance on JMP Certified Associate: Statistical Thinking for Industrial Problem Solving exam.